Non-Insulated Cord End Terminal

● max voltage:Ui=300V ● material:copper

|

Non-Insulated Cord End Terminal |

||||||

|

Max voltage : 150℃ Ui=300V |

Material : Copper |

|||||

|

ITEM NO |

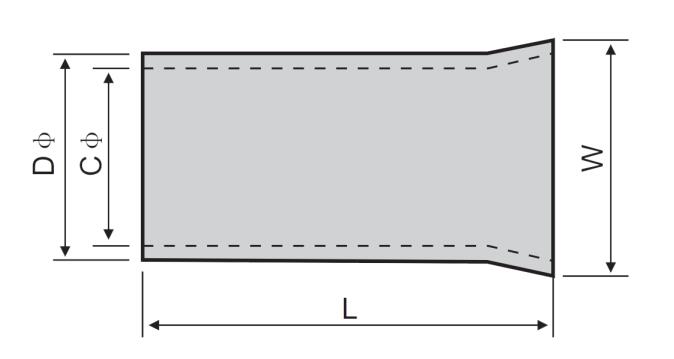

Dimension (mm) |

Cable Size |

||||

|

L |

D |

C |

W |

mm² |

A.W.G. |

|

|

EN0206 |

6.0 |

1.0 |

0.7 |

1.4 |

0.2 |

26 |

|

EN0207 |

7.0 |

1.0 |

0.7 |

1.4 |

0.2 |

26 |

|

EN0208 |

8.0 |

1.0 |

0.7 |

1.4 |

0.2 |

26 |

|

EN0306 |

6.0 |

1.1 |

0.8 |

1.5 |

0.3 |

24 |

|

EN0308 |

8.0 |

1.1 |

0.8 |

1.5 |

0.3 |

24 |

|

EN0506 |

6.0 |

1.3 |

1.0 |

1.7 |

0.5 |

22 |

|

EN0508 |

8.0 |

1.3 |

1.0 |

1.7 |

0.5 |

22 |

|

EN0510 |

10.0 |

1.3 |

1.0 |

1.7 |

0.5 |

22 |

|

EN0512 |

12.0 |

1.3 |

1.0 |

1.7 |

0.5 |

22 |

|

EN7506 |

6.0 |

1.6 |

1.3 |

1.9 |

0.8 |

20 |

|

EN7508 |

8.0 |

1.6 |

1.3 |

1.9 |

0.8 |

20 |

|

EN7510 |

10.0 |

1.6 |

1.3 |

1.9 |

0.8 |

20 |

|

EN7512 |

12.0 |

1.6 |

1.3 |

1.9 |

0.8 |

20 |

|

EN1006 |

6.0 |

1.8 |

1.5 |

2.2 |

1.0 |

18 |

|

EN1008 |

8.0 |

1.8 |

1.5 |

2.2 |

1.0 |

18 |

|

EN1010 |

10.0 |

1.8 |

1.5 |

2.2 |

1.0 |

18 |

|

EN1012 |

12.0 |

1.8 |

1.5 |

2.2 |

1.0 |

18 |

|

EN1507 |

7.0 |

2.0 |

1.8 |

2.5 |

1.5 |

16 |

|

EN1508 |

8.0 |

2.0 |

1.8 |

2.5 |

1.5 |

16 |

|

EN1512 |

12.0 |

2.0 |

1.8 |

2.5 |

1.5 |

16 |

|

EN1518 |

18.0 |

2.0 |

1.8 |

2.5 |

1.5 |

16 |

|

EN2507 |

7.0 |

2.6 |

2.3 |

3.3 |

2.5 |

14 |

|

EN2508 |

8.0 |

2.6 |

2.3 |

3.3 |

2.5 |

14 |

|

EN2510 |

10.0 |

2.6 |

2.3 |

3.3 |

2.5 |

14 |

|

EN2512 |

12.0 |

2.6 |

2.3 |

3.3 |

2.5 |

14 |

|

EN2518 |

18.0 |

2.6 |

2.3 |

3.3 |

2.5 |

14 |

|

EN4009 |

9.0 |

3.2 |

2.8 |

3.9 |

4.0 |

12 |

|

EN4012 |

12.0 |

3.2 |

2.8 |

3.9 |

4.0 |

12 |

|

EN4018 |

18.0 |

3.2 |

2.8 |

3.9 |

4.0 |

12 |

|

EN6010 |

10.0 |

3.9 |

3.5 |

4.8 |

6.0 |

10 |

|

EN6012 |

12.0 |

3.9 |

3.5 |

4.8 |

6.0 |

10 |

|

EN6015 |

15.0 |

3.9 |

3.5 |

4.8 |

6.0 |

10 |

|

EN6018 |

18.0 |

3.9 |

3.5 |

4.8 |

6.0 |

10 |

|

EN10-12 |

12.0 |

4.9 |

4.5 |

5.8 |

10.0 |

7 |

|

EN10-15 |

15.0 |

4.9 |

4.5 |

5.8 |

10.0 |

7 |

|

EN10-18 |

18.0 |

4.9 |

4.5 |

5.8 |

10.0 |

7 |

|

EN16-12 |

12.0 |

6.2 |

5.8 |

7.2 |

16.0 |

5 |

|

EN16-15 |

15.0 |

6.2 |

5.8 |

7.2 |

16.0 |

5 |

|

EN16-18 |

18.0 |

6.2 |

5.8 |

7.2 |

16.0 |

5 |

|

EN25-16 |

16.0 |

7.9 |

7.5 |

9.1 |

25.0 |

4 |

|

EN25-22 |

22.0 |

7.9 |

7.5 |

9.1 |

25.0 |

4 |

|

EN35-16 |

16.0 |

8.7 |

8.3 |

10.2 |

35.0 |

2 |

|

EN35-25 |

25.0 |

8.7 |

8.3 |

10.2 |

35.0 |

2 |

|

EN50-20 |

20.0 |

10.9 |

10.3 |

12.4 |

50.0 |

1 |

|

EN50-25 |

25.0 |

10.9 |

10.3 |

12.4 |

50.0 |

1 |

|

EN50-30 |

30.0 |

10.9 |

10.3 |

12.7 |

50.0 |

1/0 |

|

EN50-32 |

32.0 |

10.9 |

10.3 |

12.7 |

50.0 |

1/0 |

|

EN70-22 |

22.0 |

14.3 |

13.5 |

15.8 |

70.0 |

2/0 |

|

EN70-25 |

25.0 |

14.3 |

13.5 |

15.8 |

70.0 |

2/0 |

|

EN70-30 |

30.0 |

14.3 |

13.5 |

15.8 |

70.0 |

2/0 |

|

EN70-32 |

32.0 |

14.3 |

13.5 |

15.8 |

70.0 |

2/0 |

|

EN95-25 |

25.0 |

15.3 |

14.5 |

17.3 |

95.0 |

3/0 |

|

EN95-30 |

30.0 |

15.3 |

14.5 |

17.3 |

95.0 |

3/0 |

|

EN95-32 |

32.0 |

15.3 |

14.5 |

17.3 |

95.0 |

3/0 |

|

EN95-34 |

34.0 |

15.3 |

14.5 |

17.3 |

95.0 |

3/0 |

|

EN120-32 |

32.0 |

17.5 |

16.5 |

20.2 |

120.0 |

4/0 |

|

EN120-34 |

34.0 |

17.5 |

16.5 |

20.2 |

120.0 |

4/0 |

|

EN120-38 |

38.0 |

17.5 |

16.5 |

20.2 |

120.0 |

4/0 |

|

EN120-40 |

40.0 |

17.5 |

16.5 |

20.2 |

120.0 |

4/0 |

|

EN150-32 |

32.0 |

20.6 |

19.6 |

23.0 |

150.0 |

250/300 |

|

EN150-34 |

34.0 |

20.6 |

19.6 |

23.0 |

150.0 |

250/300 |

|

EN150-38 |

38.0 |

20.6 |

19.6 |

23.0 |

150.0 |

250/300 |

|

EN150-40 |

40.0 |

20.6 |

19.6 |

23.0 |

150.0 |

250/300 |

|

EN185-32 |

32.0 |

21.4 |

20.2 |

23.9 |

185.0 |

250/300 |

|

EN185-40 |

40.0 |

21.4 |

20.2 |

23.9 |

185.0 |

250/300 |