A copper terminal (or copper wire terminal) is an electrical connector used to terminate or connect copper wires to devices, switches, or other conductors. These terminals ensure a secure, conductive, and often insulated connection.

Types of Copper Terminals

Ring Terminal

Circular end with a hole for screw or bolt attachment.

Used in automotive, industrial, and panel wiring.

Spade Terminal (Fork Terminal)

U-shaped fork for easy insertion under screw heads.

Allows quick disconnection without removing the screw.

Butt Connector (Butt Splice Terminal)

Joins two wires end-to-end (as previously discussed).

Pin Terminal

Solid or hollow pin for insertion into plugs, relays, or PCB connectors.

Hook Terminal

J-shaped end for wrapping around screws or posts.

Bullet Terminal (Male/Female)

Used in automotive and trailer wiring for quick-connect applications.

Ferrule Terminal (Wire Ferrule)

Used with stranded wires in screw terminal blocks to prevent fraying.

Battery Terminal

Heavy-duty terminals for car batteries or power systems.

Key Features of Copper Terminals

Material: Pure copper or tin-plated copper for corrosion resistance.

Insulation: Many have PVC, nylon, or heat-shrink sleeves.

Sizes: Available in different wire gauges (e.g., 22 AWG to 4/0 AWG).

Crimping Required: Most need a crimping tool for a secure connection.

How to Use a Copper Terminal

- Strip the Wire – Remove insulation to expose the conductor.

- Insert Wire – Place the stripped end into the terminal barrel.

- Crimp Securely – Use a crimping tool to compress the terminal.

- (Optional) Heat-Shrink – If using insulated terminals, apply heat for a waterproof seal.

Applications of Copper Terminals

- Automotive wiring (battery, lights, sensors).

- Home & industrial electrical panels.

- Appliance and machinery wiring.

- Marine & outdoor electrical setups.

These terminals come in a vast array of types to suit different applications. Common varieties include ring, spade, hook, and butt connectors, each designed for specific mounting needs—from bolted connections to plug-in blocks. They are often made from pure copper for optimal conductivity and then plated with materials like tin, nickel, or silver to resist corrosion and enhance solderability.

The installation method is equally crucial. Terminals can be crimped, soldered, or screwed into place, with crimping being the most prevalent for its speed and the creation of a gas-tight, cold-weld joint. From the intricate circuitry of a consumer electronic device to the high-current pathways in an automotive or industrial panel, copper wire terminals are indispensable for building safe, durable, and efficient electrical systems. Their simple design belies their vital role in ensuring every connection is both mechanically robust and electrically sound.

What are the main types of copper wire terminals?

Copper wire terminals come in various designs to suit different applications. The common types include ring terminals, spade terminals, fork terminals, butt connectors, and bullet terminals.

- Ring terminals provide a secure connection by fitting around a bolt or stud.

- Spade terminals have a fork shape, allowing attachment without fully removing the screw.

- Butt connectors are used for end-to-end wire joining.

- Bullet terminals enable quick plug-in and removal, ideal for circuits that may need frequent disconnection.

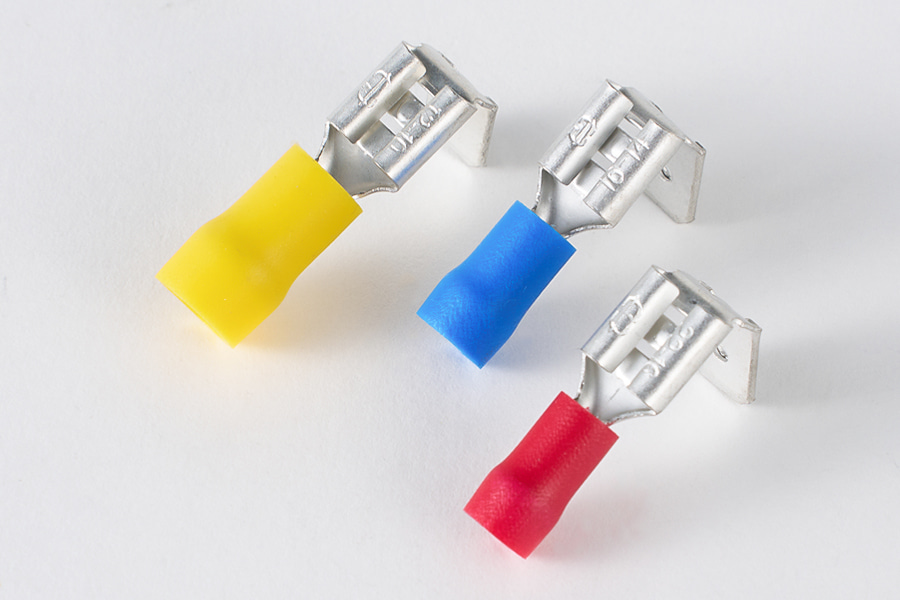

- Each type is available in insulated and non-insulated forms, with insulation colors typically corresponding to wire gauge compatibility.

Why is copper preferred over other metals for wire terminals?

Copper's high electrical conductivity ensures minimal energy loss and voltage drop. It is also ductile, allowing easy crimping without breaking strands, and resistant to corrosion, which prolongs the terminal's service life. While alternatives like aluminum are lighter and cheaper, copper maintains performance in low- to medium-voltage applications.

How do I ensure a secure connection with copper wire terminals?

A reliable connection depends on proper wire preparation, terminal selection, and crimping technique. Begin by stripping the insulation correctly, ensuring no wire strands are damaged. Choose a terminal sized for the wire gauge and intended application. Use a crimping tool to compress the terminal evenly, securing both the wire and insulation. Finally, inspect the connection for tightness and stability; a gentle pull test helps confirm that the wire is firmly held. Proper installation prevents loose connections, arcing, or heat buildup, ensuring safe and efficient operation.

Copper wire terminals are versatile and dependable connectors. Understanding their types, material advantages, and installation techniques ensures consistent electrical performance across various applications.

How Do Non-Insulated Wire Connectors Compare to Insulated Wire Connectors?

Design and Structure

Non-insulated wire connectors consist solely of a metal conductor, typically copper or brass, without any protective covering. Their design allows for conductivity and compact size, which is advantageous in tight spaces. These connectors rely on external insulation, such as electrical tape or heat-shrink tubing, to prevent short circuits.

Insulated wire connectors, on the other hand, incorporate a plastic or nylon housing around the metal barrel. The insulation not only protects users from accidental contact but also prevents electrical shorts and mechanical strain on the wire. Common insulation colors indicate the wire gauge range compatible with the connector, simplifying selection.

Installation and Handling

Non-insulated connectors generally require more careful handling. Because the metal is exposed, any accidental contact can result in short circuits or shock if the circuit is live. Installation usually involves crimping or soldering, followed by an additional insulation step.

Insulated connectors simplify installation. The plastic or nylon sleeve allows users to handle the connector safely and crimp it directly onto the wire. Some insulated connectors are even designed for tool-free connections, such as quick-splice terminals, reducing installation time and effort.

Electrical Performance

From a conductivity standpoint, non-insulated connectors provide slightly better performance because there is no insulating layer to create a small thermal barrier. They are often preferred in high-current applications where resistance must be minimized.

Insulated connectors, while slightly less conductive due to the surrounding material, are engineered to maintain low resistance within their rated current range. The insulation also protects the connection from environmental factors like moisture, dust, and vibration, which can degrade conductivity over time.

Applications and Safety Considerations

Non-insulated connectors are commonly used in controlled or enclosed environments, such as inside industrial panels, control boxes, or machinery where accidental contact is impossible. They are also useful where high-density wiring requires compact connections.

Insulated connectors are ideal for open or exposed wiring, such as automotive wiring harnesses, household circuits, and outdoor electrical equipment. Their insulation enhances safety, prevents accidental shorts, and increases durability under vibration and mechanical stress.

Cost and Convenience

Non-insulated connectors are typically less expensive, as they do not require additional plastic or nylon materials. However, installation may take more time due to the need for added insulation.

Insulated connectors are slightly costlier but offer time-saving benefits and improved safety. They are often sold in standardized color codes, allowing quick identification and selection during installation, particularly in large projects.

|

Feature |

Non-Insulated Connectors |

Insulated Connectors |

|

Protection |

None, relies on external insulation |

Built-in plastic or nylon sleeve |

|

Safety |

Lower, risk of accidental contact |

Higher, protects against shocks and shorts |

|

Ease of Installation |

Requires additional insulation steps |

Ready to use, faster installation |

|

Electrical Performance |

Slightly better, direct metal contact |

Slightly lower, but sufficient for rated current |

|

Cost |

Lower |

Slightly higher |

|

Applications |

Enclosed panels, high-current wiring |

Automotive, household, outdoor wiring |

English

English Español

Español Deutsch

Deutsch